![]()

![]()

![]()

![]()

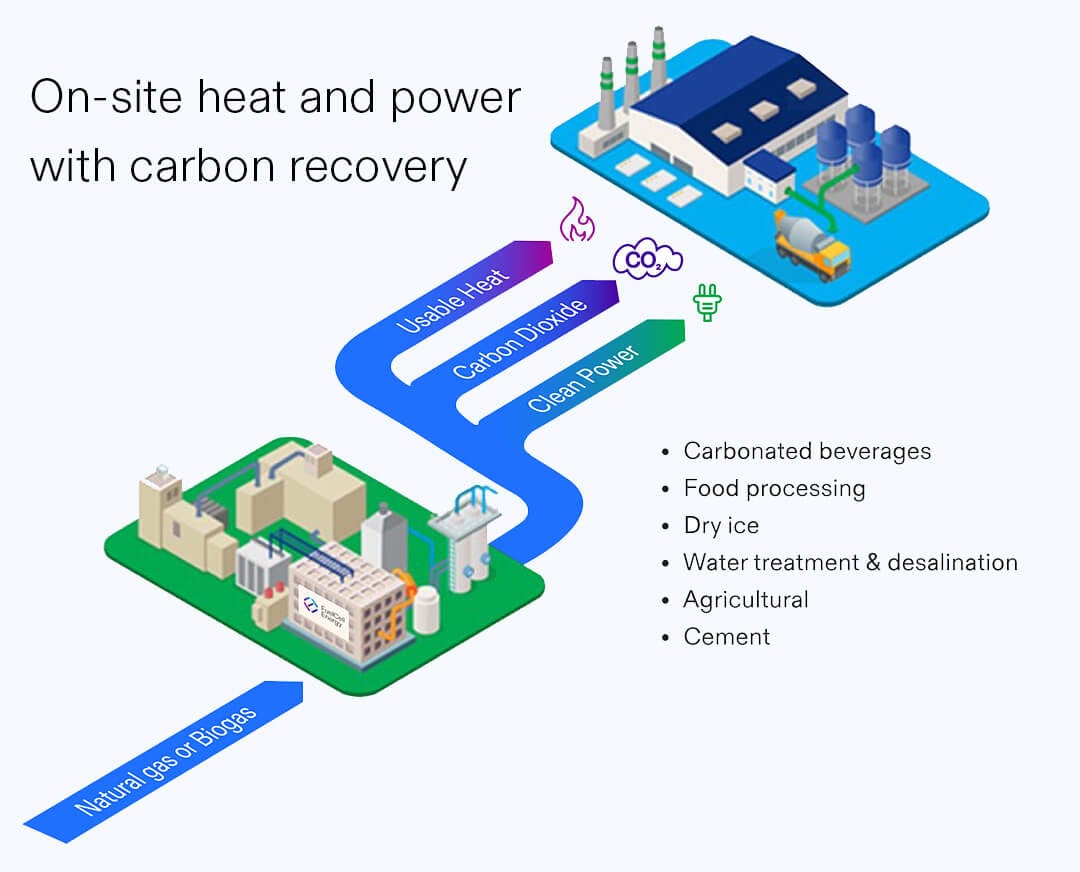

Businesses are setting aggressive net-zero targets as the planet looks to reduce emissions. FuelCell Energy presents a compelling opportunity for manufacturers to make progress on their sustainability goals. Our plant's electrochemical process results in electricity, heat, and water, with the ability to recycle CO2 into a valuable product.

Once captured and concentrated by the fuel cells, the CO2 has many potential uses. CO2 can be used for beverage bottling, food processing, cooling, welding, dry ice production, metal fabrication, water treatment, fire suppression, and to aid in the production of cement and plastics.

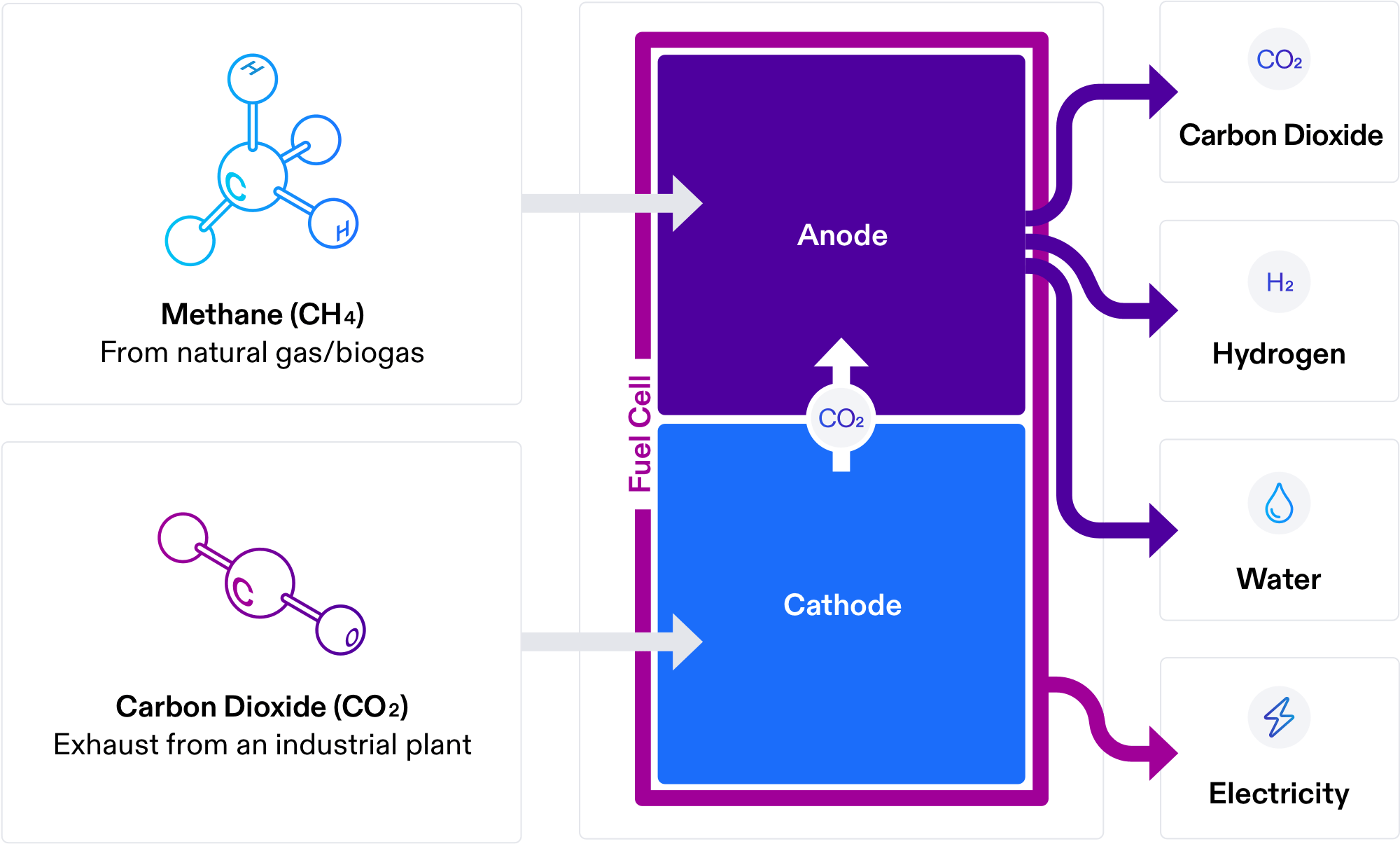

Fuel cells use an electrochemical process to convert hydrogen-rich fuels into electrical power and heat. Inside the fuel cell, methane is steam-reformed at 600 degrees Celsius and converted into hydrogen and carbon dioxide (CO2). The fuel cell produces electricity, heat, and water, while recycling CO2 into a valuable product.

Fuel cells can reduce emissions and bring circularity to your CO2 supply chain. Learn how fuel cells can capture CO2 for on-site use in this video.

.jpg?width=800&height=450&name=Virtual%20CO2%20Recovery%20Tour%20(1).jpg)

Learn how fuel cells can recover CO2 while producing low-carbon electricity. Step through an animated walkthrough of the system.

FuelCell Energy's platforms provide the majority of power to a state-of-the-art bakery facility in Bloomfield, Connecticut. The 260,000-square-foot manufacturing facility runs three shifts and relies on on-site power from its fuel cell system.

Heat from the fuel cell plant is used to support bakery operations, which helps reduce fuel needs for plant boilers. When used in combined heat and power applications (CHP), the overall system efficiency can be up to 80 percent, using fewer resources to produce more power.

FuelCell Energy’s team is here to support you every step of the way. We’ll work to learn the details of your operation and recommend the best configuration to meet your goals. Let us know how we can help.

Idaho National Laboratory Testing of FuelCell Energy’s Electrolyzer to Show Further Commercialization Opportunity for Nuclear Power Plants Learn more