Carbon dioxide (CO2) is the most produced greenhouse gas. The gas can be released naturally from activities like volcanic eruptions or from human activities like industrial processes. Too much greenhouse gas in the air can cause the climate to warm in unsustainable ways. Countries, trade associations, and leading corporations have set aggressive net zero targets to reduce greenhouse gas emissions. Fuel cell technology presents a compelling opportunity for manufacturers to recycle CO2 while producing power.

CO2’s crucial role in our everyday products and supply chain can often go unnoticed to the everyday consumer. The gas is used in a variety of processes including refrigeration, dry ice for pharmaceuticals, extending the shelf life of food, carbonating beverages, purifying water, and more.Early in the pandemic, the CO2 shortage was felt throughout the food supply chain, even forcing some breweries to shut down in the United States. Food and beverage producers rely on CO2 to carbonate products like seltzer and beer. In fact, most beers would be unrecognizable without that refreshing fizz, making CO2 a commodity sometimes referred to as “liquid gold.” This demand is expected to grow even more as the popularity of low-calorie and low-sugar alcoholic drinks drives significant growth in the hard seltzer market.

Today, CO2 is transported to the end point of use, often over long distances and at high costs. Inconsistent CO2 availability over the last few years has caused industry leaders to write to the federal government asking for relief. Fuel cell plants can be a reliable source of CO2 for operations that rely on the gas in their production.

How does it work?

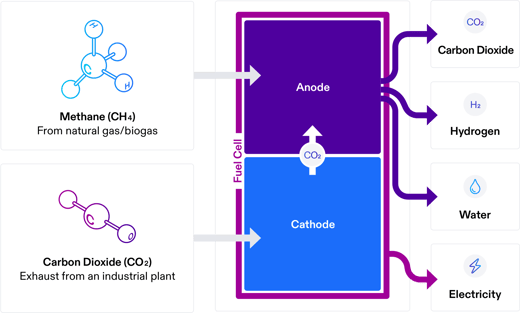

Fuel cells use an electrochemical process to convert hydrogen-rich fuels into electrical power and heat. Inside the fuel cell, methane is steam-reformed at 700 degrees Celsius and converted into hydrogen and carbon dioxide (CO2). The fuel cell produces electricity, heat, and water while recycling CO2 into a valuable product. Producing onsite heat and power can help facilities avoid costly downtime associated with power outages.

The energy transition will be a collaborative effort that involves business leaders and a number of promising technologies. FuelCell Energy’s platforms complement the existing systems of many industrial facilities—providing a real-world path to reduce on-site emissions. By producing CO2 on site, businesses reduce their exposure to supply chain disruptions, trucking costs, and price fluctuations. Businesses may even sell their excess CO2 as an end-product to third parties.

Businesses are looking to make measurable progress on their sustainability goals. FuelCell Energy’s platform presents an opportunity for businesses to make measurable progress on net zero ambitions. By generating heat, electricity, and compressed CO2, fuel cells create valuable resources and ultra-clean energy while reducing emissions. The application can be particularly useful for food and beverage manufacturers who use CO2 in their production process.

FuelCell Energy recently released a “Carbon Savings Calculator” that provides an estimate of how much an organization can save by recycling their CO2.